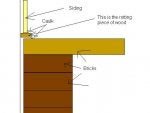

I'm currently painting a house that has brick on the lower half of some exterior walls, and there's a thin strip of wood (maybe masons have a term for it) between the siding and the brick that looks like it was painted and caulked when the house was built, but that paint has since flaked off and the wood is disintegrating, which allows stuff to get behind the brick. How would I go about replacing that piece of wood (or is calling a mason the better choice)?

sgrprince

Wood Between Siding and Brick

sgrprince

Discussion starter

16 posts

·

Joined 2006

- Add to quote

I'm currently painting a house that has brick on the lower half of some exterior walls, and there's a thin strip of wood (maybe masons have a term for it) between the siding and the brick that looks like it was painted and caulked when the house was built, but that paint has since flaked off and the wood is disintegrating, which allows stuff to get behind the brick. How would I go about replacing that piece of wood (or is calling a mason the better choice)?

140 posts

·

Joined 2007

Water table? Your mason might have removed headers or rollock bricks, might be a easier to remove it on top depending on exterior finish on top of trim ,Is it stucco?

1 post

·

Joined 2007

First you need a carpenter.Hopefully you can slip some flashing behind the siding.The original was of poor design.That's why it rotted.

140 posts

·

Joined 2007

The problem could be that those top header bricks are level ,that allows water to run inside and create rot and water damange inside the house.Big No No! Those brick need to be relaid at min 1/4'' pitch away from the veneer. You could be doing some serious work.My advice is tearing out headers & top siding .Replace the watertable(wood trim) & raising it up 3/8'' . Check the waterproof backing too.

1,231 posts

·

Joined 2006

what this was is a reciver for the brick rolock.it was more than likely made of pine or some other soft wood and that is the reason is is falling apart.you should be able to remove it and replace it with redwood or some treated lumber and repaint it and recaulk,with no need for a mason.

posted this before before subia's post was up.i agree 100% if there is no pitch away from the house,this problem will continue and only get worse.i was called out on a house where two windows were leaking,from the sill.i discovered that the brick sill actually sloped back into the house.it was a quick fix,and saved the homeowner alot of problems down the road.

posted this before before subia's post was up.i agree 100% if there is no pitch away from the house,this problem will continue and only get worse.i was called out on a house where two windows were leaking,from the sill.i discovered that the brick sill actually sloped back into the house.it was a quick fix,and saved the homeowner alot of problems down the road.

sgrprince

Discussion starter

16 posts

·

Joined 2006

The top bricks actually are at a slight slope, sorry I didn't draw that. The piece of wood looks like it's slightly thicker behind the siding, and was placed there before the siding was installed, which means it probably can't be removed without removing the siding (or just wrecking the siding). Does my replacement piece need to be a wedge shape like the original, or will a flat piece be ok? If it needs to be a wedge, would a masonry supply place have a replacement, or is this something that I would need to make myself?

1,231 posts

·

Joined 2006

the reciver should be cut at an angle also. i take a 2x4 and cut it at 22 1/2 degree angle.

808 posts

·

Joined 2004

Kevin's Fix

saw sall out the woodwater table. Have a piece of cedar or redwood sill milled about 12-14 degrees [same pitch as window sill] Also there needs

to be a drip grove dadooed in W/table. On the west coast this stock is available in our lumber yards, [w/o groove]. Stock should be 1 1/2" thick.

Just look at the detail on an OLD wood window.Yes, You need flashing! At a min use pollyurathane calk. It's all i use. It's the caulking used on Hi risers. THE BEST. I have a large shop ,woodwork and welding. We could run this for You in a heartbeat. Any REAL carp can ,find one. It's getting harder ,all the time to . Good luck!

saw sall out the woodwater table. Have a piece of cedar or redwood sill milled about 12-14 degrees [same pitch as window sill] Also there needs

to be a drip grove dadooed in W/table. On the west coast this stock is available in our lumber yards, [w/o groove]. Stock should be 1 1/2" thick.

Just look at the detail on an OLD wood window.Yes, You need flashing! At a min use pollyurathane calk. It's all i use. It's the caulking used on Hi risers. THE BEST. I have a large shop ,woodwork and welding. We could run this for You in a heartbeat. Any REAL carp can ,find one. It's getting harder ,all the time to . Good luck!

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 3.6M

- members

- 170K

- Since

- 2003

A forum community dedicated to professional construction and remodeling contractors. Come join the discussion about the industry, trades, safety, projects, finishing, tools, machinery, styles, scales, reviews, accessories, classifieds, and more!

Explore Our Forums