I have 2 questions.

1. Do you block your rafter tails (not trusses)

2. Is this code to block rafter tails?

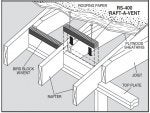

The reason why I am asking is that today, a wide, wide gap in techniques reared it's head. I have always put rafter blocks in, every time, with a 1" air gap minimum at the top for airflow to the bays. Like this.

![Image]()

I was told today that it is not done, it is not necessary, it is overkill, no one does it, it doesn't do anything, waste of time. Even on raised heel trusses, not done. Our raised heel is about 18" HAP.

Found a small section in the code book about it, wasn't too detailed.

1. Do you block your rafter tails (not trusses)

2. Is this code to block rafter tails?

The reason why I am asking is that today, a wide, wide gap in techniques reared it's head. I have always put rafter blocks in, every time, with a 1" air gap minimum at the top for airflow to the bays. Like this.

I was told today that it is not done, it is not necessary, it is overkill, no one does it, it doesn't do anything, waste of time. Even on raised heel trusses, not done. Our raised heel is about 18" HAP.

Found a small section in the code book about it, wasn't too detailed.