I am not on the job making sawdust. I'm in a darkened room making construction documents that carpenters will use to build.

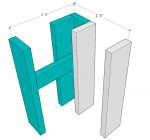

Where an interior wall tees into an exterior wall I specify not a cluster of studs, but 2x horizontal blocking in the exterior bay or bays for the tie-in.

Less timber, more void for insulation. 24-inch centers for the cats gives all one needs for sheetrock fastening.

For the outside corners, I specify a three-stud corner plus the inside horizontal blocking for sheetrock, if the job has claps and cornerboards for exterior finish. If the outside is stucco, I go with a two stud corner and the 2x4 cats.

Again, as little timber as possible and more void for insulation.

Where an interior wall tees into an exterior wall I specify not a cluster of studs, but 2x horizontal blocking in the exterior bay or bays for the tie-in.

Less timber, more void for insulation. 24-inch centers for the cats gives all one needs for sheetrock fastening.

For the outside corners, I specify a three-stud corner plus the inside horizontal blocking for sheetrock, if the job has claps and cornerboards for exterior finish. If the outside is stucco, I go with a two stud corner and the 2x4 cats.

Again, as little timber as possible and more void for insulation.