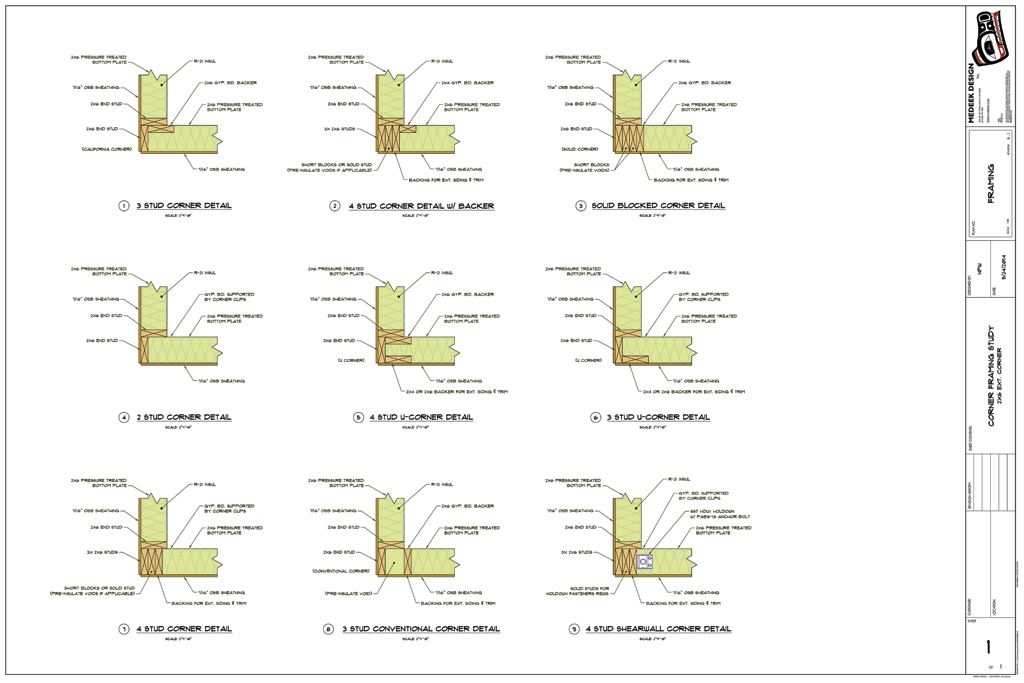

OK, question #2 on the differences between framing w/ 2x4s or 6s

How do you build corners for 2x6 walls?? when you build corners for 2x4 walls, you have that extra 1" nailer for your drywall later on. what about 2x6s??

Many thanks for the help framer folk!

MHM arty:

arty:

How do you build corners for 2x6 walls?? when you build corners for 2x4 walls, you have that extra 1" nailer for your drywall later on. what about 2x6s??

Many thanks for the help framer folk!

MHM